Recycled Steel Tyre Microfibres

High-Performance Micro-Reinforcement from Recycled Tyres

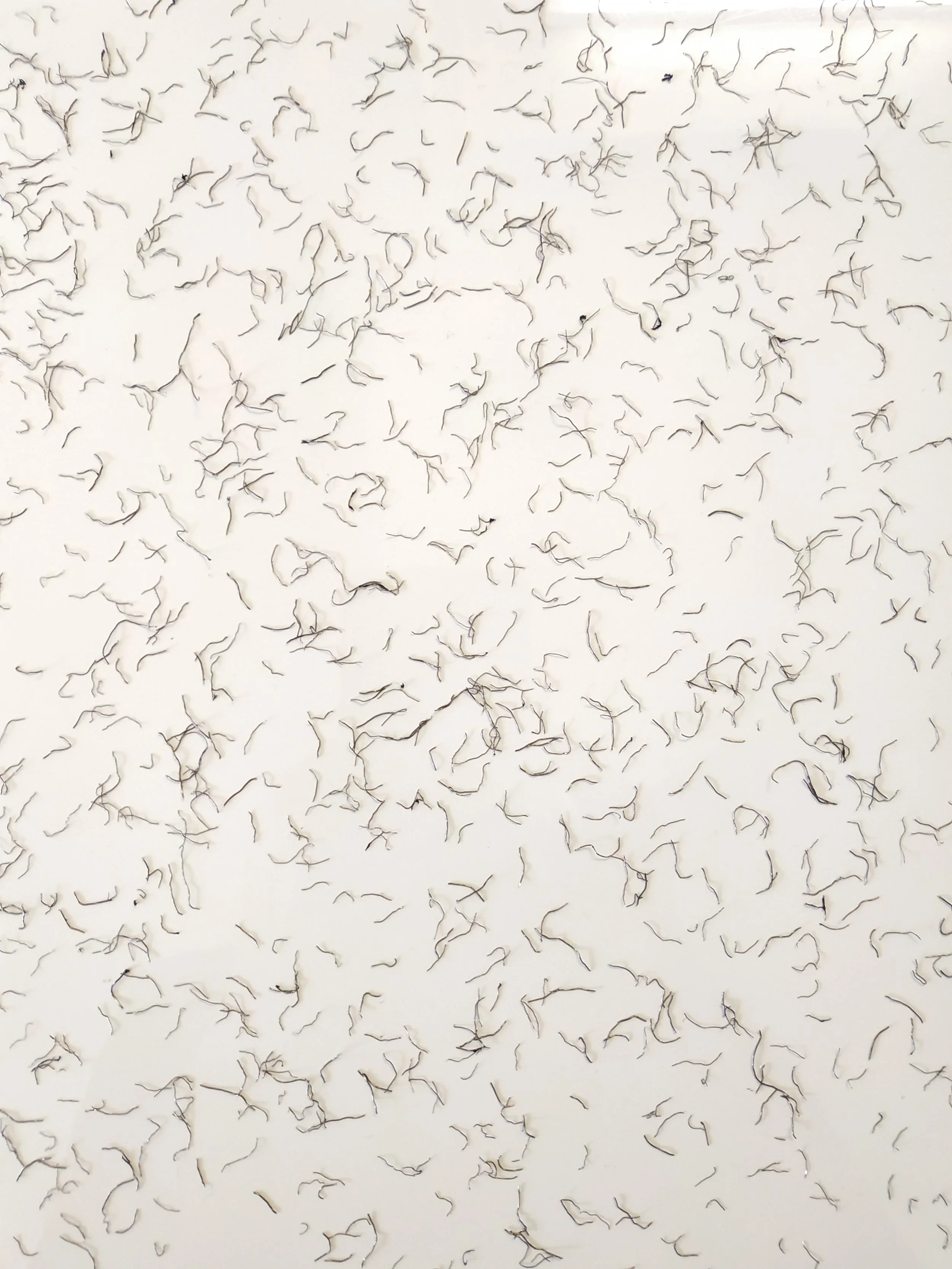

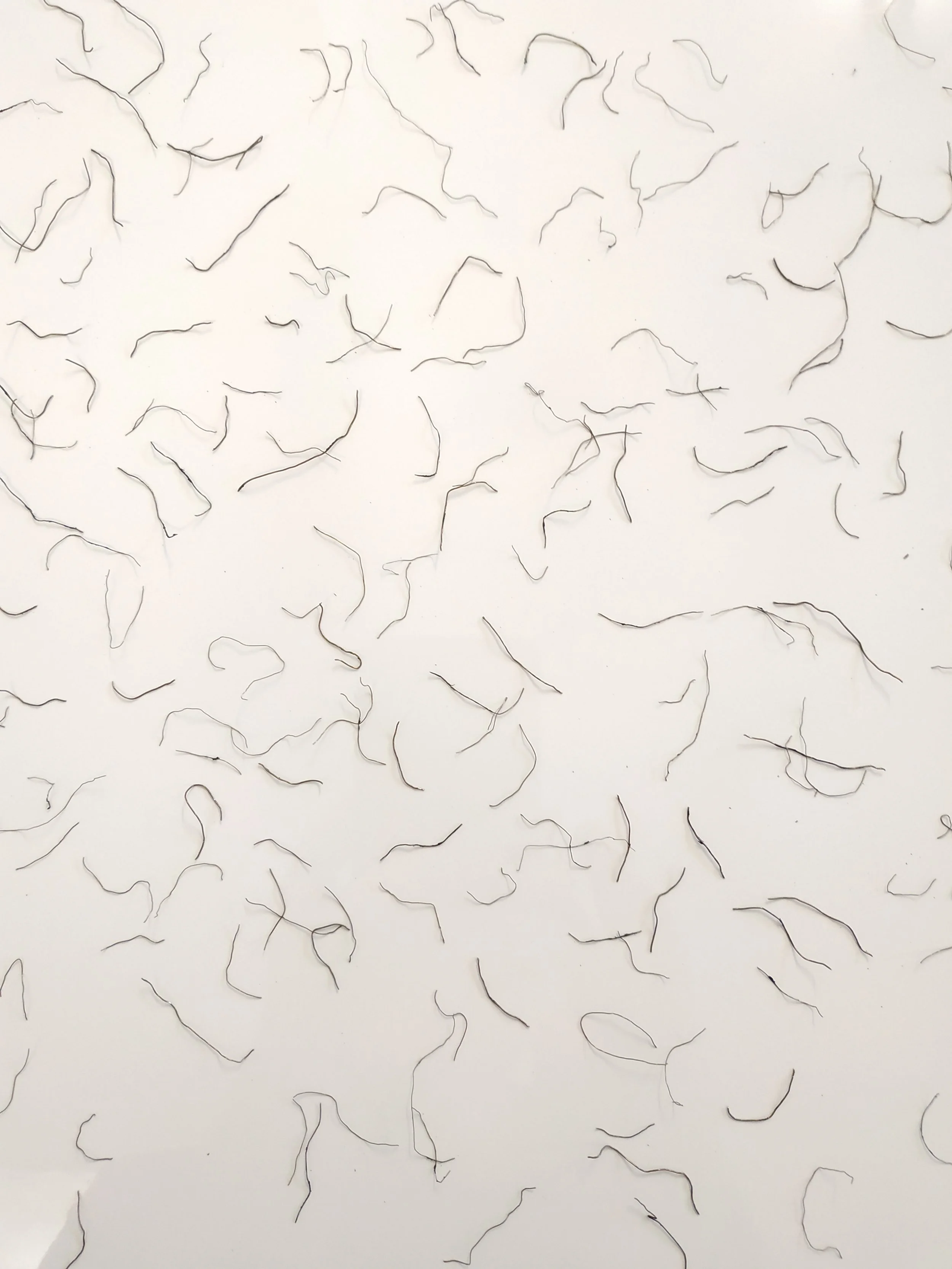

Recycled Steel Tyre Microfibres (RSTM) are ultra-fine steel fibres recovered from End-of-Life tyres, offering a sustainable and cost-effective alternative to conventional steel fibres.

These fibres form a dense reinforcing network within concrete, mortar and grout, providing excellent micro-crack control and enhanced durability.

Sustainable Innovation

By repurposing high-tensile steel from recycled tyres, RSTM supports a circular economy while delivering up to 95% lower carbon emissions compared with new steel production. This process reduces waste, conserves resources and promotes responsible construction practices.

Key Benefits

Superior micro-crack & shrinkage control

High fibre count & uniform dispersion

Lower carbon footprint and reduced resource use

Up to 50% cost savings compared with traditional steel fibres

Compatible with macro fibres for enhanced structural performance

Consistent quality

Applications

Ultra High Performance Concrete

Industrial and commercial floors, toppings and overlays

Mortars, screeds and grouts

Precast elements, repair mortars and patching

Shotcrete and tunnel linings

3D-printed concrete and extrudable mixes

Thin sections where finish quality matters

Build Responsibly. Reinforce Efficiently.

RSTM delivers dependable micro reinforcement, combining strength, sustainability and value for a lower carbon built environment.

Contact us to learn how Recycled Steel Tyre Microfibres can improve performance and sustainability in your next project.

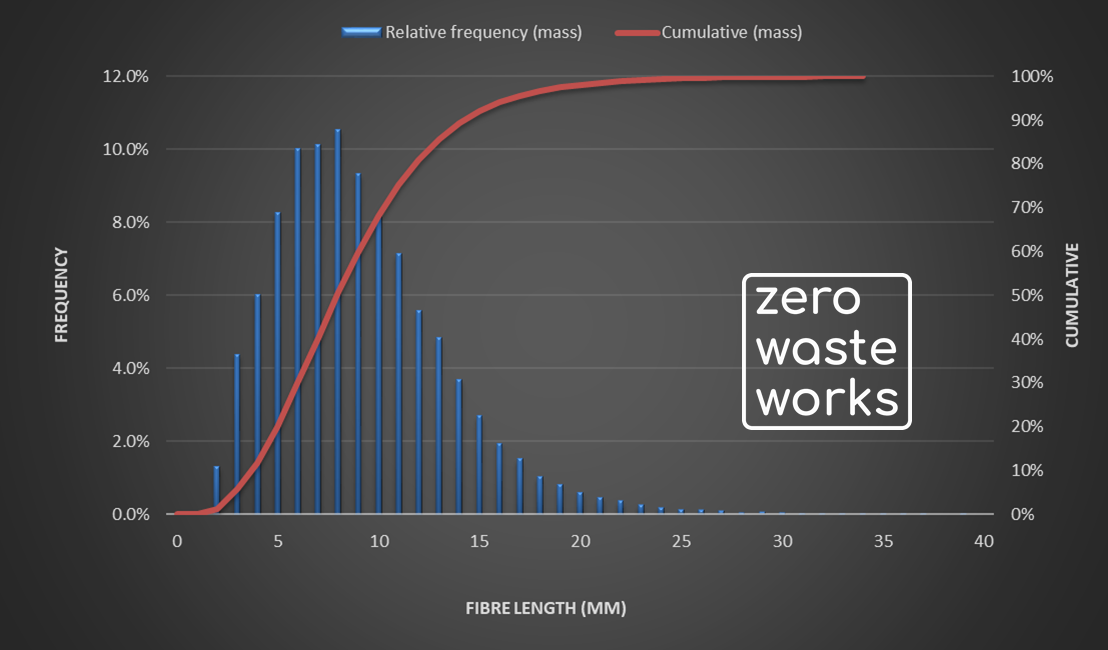

RSTM5-15/.1-.4 for Ultra High Performance Concrete:

Length range: 5-15mm (~80% by mass)

Diameter range: 0.1-0.4mm

Tensile Strength: min 2,000 MPa

RSTM15-30/.1-.4 for Normal & High Strength Concrete

Length range: 15-30mm (~80% by mass)

Diameter range: 0.1-0.4mm

Tensile Strength: min 2,000 MPa